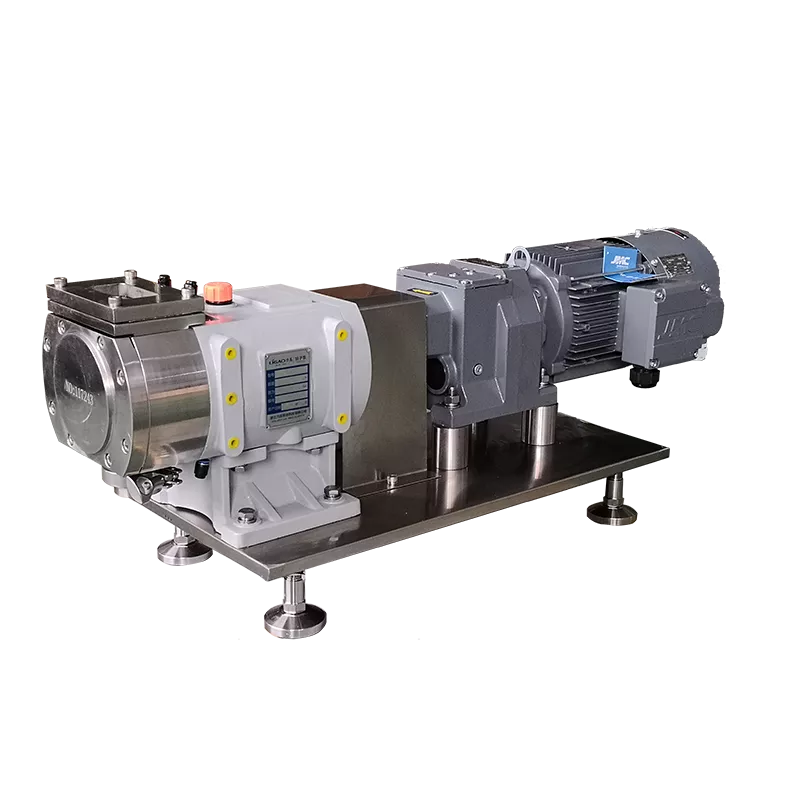

Rotary Lobe Pumps

WRS rotary lobe pump are designed for sanitary/food grade applications. All wetted parts are made in Stainless Steel and the sealing parts are non-toxic gasket. The streamline structure of the rotor pump creates an absence of dead spots and scrap metal free in the rotor chamber, this prevents contamination of the pumping medium. It is also suitable for CIP cleaning application, fully comply to the American FDA and GMP standards.

Features:

- Able to handle foaming medium such as soup, cleaning detergent etc.

- Able to handle high viscosity medium up to 1,000,000 CP.

- Able to handle mixture medium of gas, fluid, solids. Slurry medium up to 55% solids.

- External dynamic and static ring mechanical seal design. Pump can be flush with water, leak free design and robust sealing. Able to handle high temperature and high-pressure application.

- Small size yet high performance. High capacity and pressure, suitable for long distance transfer application.

- The pump is designed to have a minimum clearance between the impeller, transmission gear, pump casing and others moving parts in the pumping chamber. Each of them is not in contact or rubbing on each other. In results, providing a long-lasting quality, stable pumping performance, low noise level and low energy consumption. Giving user the most efficient way of pumping experience.

- Minimum wear and tear parts design. Reducing cost of maintenance for the user.

RP Models Rotary Lobe Pump Specifications

| Model | L/round | Flowrate (m3/h) | RPM | Max. Pressure MPa | Power Range (kW) | Clamp Connection | Flange Connection |

| RP1 | 0.05 | 0 – 1 | 40 – 700 | 1 | 0.25 – 1.5 | 1″ | DN20 |

| RP2 | 0.1 | 0.2 – 2 | 40 – 700 | 1.2 | 0.55 – 2.2 | 1 1/4″ | DN25 |

| RP3 | 0.17 | 0.4 – 3 | 40 – 500 | 1.2 | 0.75 – 3.0 | 1 1/2″ | DN32 |

| RP5 | 0.26 | 0.6 – 5 | 40 – 500 | 1.5 | 1.5 – 5.5 | 2″ | DN40 |

| RP8 | 0.46 | 1 – 8 | 40 – 450 | 1.5 | 2.2 – 11 | 2 1/2″ | DN50 |

| RP12 | 0.7 | 1.6 – 12 | 40 – 450 | 1.5 | 3.0 – 15 | 2 1/2″ | DN50 / DN65 |

| RP20 | 1.2 | 2.8 – 20 | 40 – 400 | 1.5 | 4.0 – 18.5 | 3″ | DN65 / DN80 |

| RP35 | 2.1 | 5 – 35 | 40 – 400 | 1.5 | 7.5 – 30 | 4″ | DN100 |

| RP55 | 4.2 | 10 – 55 | 40 – 350 | 1.5 | 11 – 45 | DN125 | DN125 |

| RP80 | 6.7 | 16 – 80 | 40 – 350 | 1.5 | 15 – 75 | DN125 / DN150 | DN125 / DN150 |

| RP120 | 11.0 | 26 – 120 | 40 – 300 | 1.5 | 22 – 90 | DN150 | DN 150 |

RT Models Rotary Lobe Pump Specifications

| Model | Liters/Round | Flowrate (m3/h) | RPM | Max Pressure (MPa) | Viscosity Range (Cp) | Power Range (kW) | Clamp Connection | Flange Connection |

| RT006 | 0.06 | 1 | 20 – 1000 | 0.8 | 1 – 500000 | 0.25 – 1.5 | 1″ | DN25 |

| RT015 | 0.15 | 2 | 20 – 700 | 1.5 | 1 – 1000000 | 0.55 – 2.2 | 1 1/2″ | DN32 |

| RT032 | 0.32 | 5 | 20 – 500 | 1.5 | 1 – 1000000 | 0.75 – 4.0 | 2″ | DN50 |

| RT070 | 0.70 | 10 | 20 – 500 | 1.5 | 1 – 1000000 | 1.5 – 7.5 | 2.5″ | DN65 |

| RT170 | 1.70 | 20 | 20 – 500 | 1.5 | 1 – 1000000 | 2.2 – 15 | 3.5″ | DN80 |

| RT320 | 3.20 | 35 | 20 – 400 | 1.5 | 1 – 1000000 | 3.0 – 30 | 4″ | DN100 |

| RT500 | 5.00 | 50 | 20 – 400 | 1.2 | 1 – 1000000 | 5.5 – 45 | 5″ | DN125 |

| RT700 | 7.00 | 80 | 20 – 400 | 1.2 | 1 – 1000000 | 7.5 – 55 | 6″ | DN150 |