Solenoid Driven Dosing Pump

Looking for solenoid dosing pump? We are authorized agent for WRS pumps in Singapore. A dosing pump, also commonly known as metering pump or chemical injection pump. It is categorized under positive displacement pump family. The main purpose of a dosing pump is to accurately dose chemical into a system. There are various type of dosing pump such as piston, peristaltic, diaphragm and hydraulic diaphragm. ML & ML-S dosing pump is a microprocessor-controlled solenoid diaphragm type dosing pump.

The main difference between ML and MLS series is the option for connecting to a signal control source. The MLS model have an additional plug for pulse signal or 4-20mA signal. While the ML model does not have this plug. Other than that, all parameters are the same.

Common Applications:

- Potable water treatment: Metering of disinfectants

- Cooling circuits: Metering of corrosion inhibitors and biocides

- Wastewater treatment: Metering of flocculants

- Paper industry: Metering of additives

- Plastics production: Metering of additives

Solenoid Dosing Pump Performance Parameters

| Model | Flowrate (Lph) | Max. Pressure (Bar) | Stroke Per Minute (min -1) |

| ML / MLS 0001 | 1 | 10 | 80 |

| ML / MLS 0002 | 2 | 10 | 140 |

| ML / MLS 0004 | 4 | 8 | 180 |

| ML / MLS 0005 | 5 | 5 | 140 |

| ML / MLS 0008 | 8 | 4 | 170 |

| ML / MLS 0010 | 10 | 3 | 130 |

| ML / MLS 0012 | 12 | 3 | 150 |

| ML / MLS 0015 | 15 | 2 | 160 |

| ML / MLS 0020 | 20 | 1.5 | 180 |

Features:

- Small size and easy installation.

- Simple control design, control everything with only three buttons.

- Specially designed for handling corrosive liquids.

- Varieties of material options, for different applications.

- Controllable flowrate at both working and non-working condition.

- Simple way to release air or retrieving sampling from the system through the air release valve right at the discharge.

- Compact modular design.

- Simple LED display.

- Check valve with double balls designed for easy maintenance.

- Accessories are included.

- Wear-free solenoid driving, without any bearing.

- Newly designed high-performance PCB. Perfectly match the magnetic drive, providing strong drive power.

How does it work?

Solenoid metering pump is the use of electromagnetic push rod driven diaphragm in the pump head reciprocating movement, causing the pump head chamber volume and pressure changes. Changes in pressure caused by suction valve and discharge valve opening and closing, to achieve quantitative liquid suction and discharge. A magnet moves the solenoid shaft forwards and backwards by switching on and off. This stroke movement is transferred to the diaphragm in the dosing head. Two non-return valves prevent the feed chemical from flowing back during pumping and the stroke length and stroke rate can be adjusted to alter the capacity of a solenoid-driven metering pump.

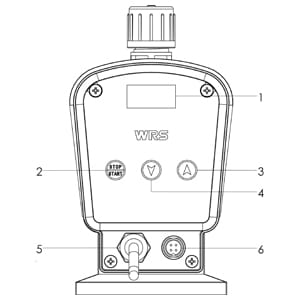

1. Frequency Display, 2. Start/Stop Button, 3. Increase Button, 4. Decrease Button, 5. Power Cable, 6. Signal Plug(Only for ML-S)

What are the advantages?

A solenoid dosing pump is designed with only one moving part, the drive is virtually wear-free. The pump requires no lubricated bearings or shafts therefore the maintenance and repair costs are therefore very low. The continuous running characteristics are excellent.

How to choose a solenoid dosing pump?

- Specify pump capacity in litres per hour [l/h]

- Specify back pressure in bar

- Find the intersection of these two values and select the pump type that lies nearest to it